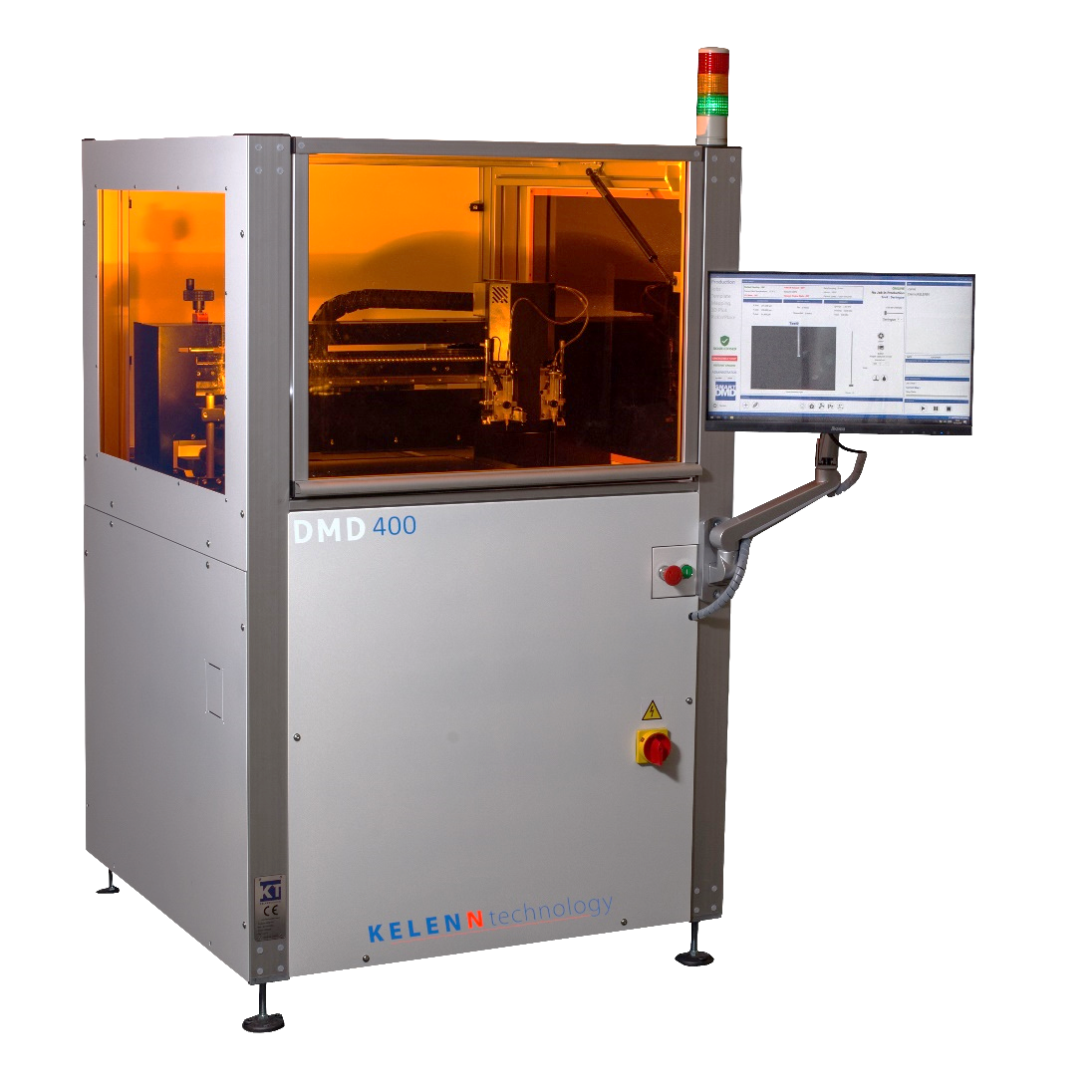

DMD400

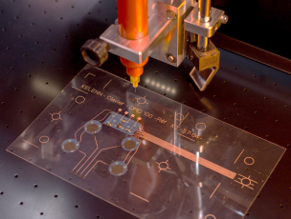

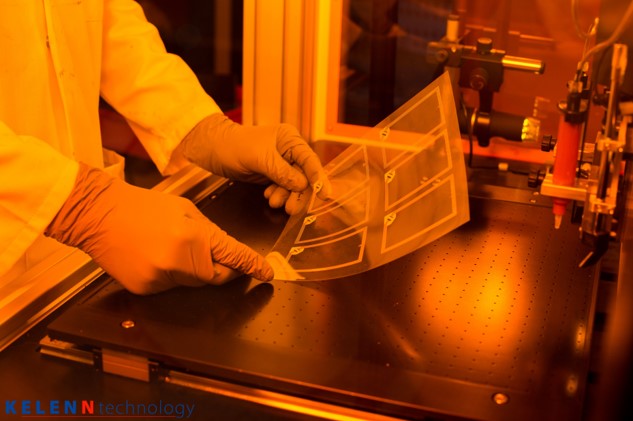

The DMD400® system prints any fonctional fluidic material on upto 400x400 mm planar substrates and up to 40 mm height 3D substrates with disposable cartridges.Thanks to a sophisticated and easy to use software, a fully automated print process of multiple layers, a pick and place of electronics components and an industrial setup, the DMD400 accelerates our customer’s design and production cycles.

Technical characteristics

- Minimum track width : 30 µm

- Precision of the three axis : 5 µm

- Viscosity range : 10 cps to 50 000 cps

- Thermal and UV post treatment

- Vacuum flat bed 400 x 400 mm temperature controled

- Camera inspection

- One or two digital dispensers

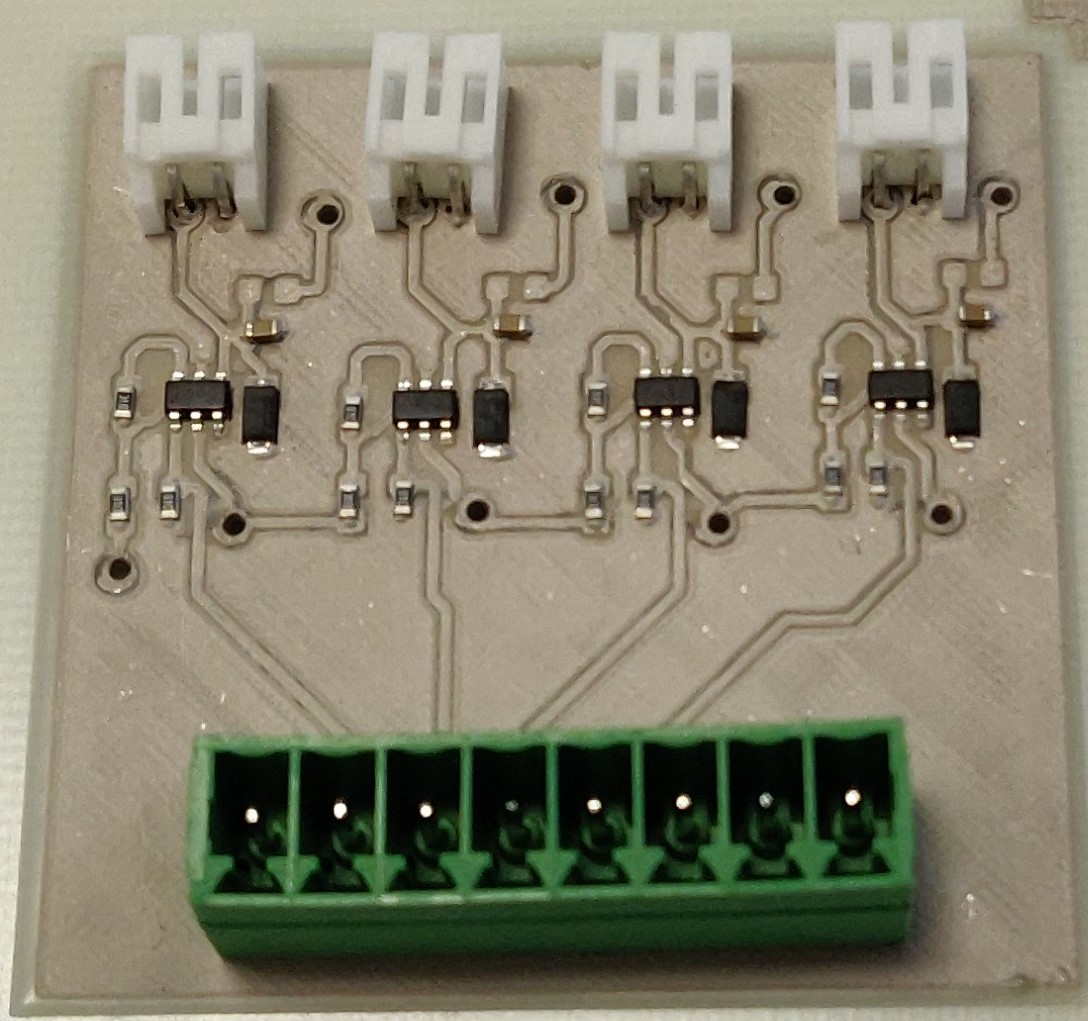

- Pick and place of electronics commponents

- Full featured software for 2,5D design and production

- Drop angle & pendant drop measurement

Possibilities and applications

The DMD400® is best suited for various applications such as:

- Electronics including : RFID tags (NFC & UHF), Bluetooth, batteries, Strechable electronics, Structural electronics, Printed circuit boards, IoTs, Flexs, Plastronics, Photo voltaic,...

- Biological fluids, organic polymers patterning,...

Typical activities include:

- Prototypes

- Production runs

- Development of new process for digital or analog production such as screen printing

- Evaluation of material and substrate interaction